Parkson/Manion Engineering Upgrades Montana Plant for Nutrient Removal Requirements

FORT LAUDERDALE, FL - Parkson Corporation is delivering a Biolac® System activated sludge process to a Montana treatment plant, making it one of the first operators in the region to satisfy tough new standards for ammonia, nitrogen and phosphorous removal.

Parkson worked with a Missoula, Montana based firm, Manion Engineering, to develop this low-cost, nutrient removal solution for cold weather based communities in the northern reaches of the United States. The first treatment plant offering this caliber of performance is currently under construction in Dillon, Montana by Dick Anderson Construction and is expected to be on-line in early 2014.

“Montana, North Dakota and other nearby states are very aware of the concerns from ammonia, nitrogen and phosphorous in the liquid stream,” said John Manion, founder of Manion Engineering.

“We want to address this problem head on by retrofitting existing treatment plants with a low-cost solution that is reliable and sustainable for the years to come for communities with these nutrient removal criteria’s; as mandated by EPA/DEQ.”

Dillon, Montana is a 1 MGD waste water treatment facility that services the nearby ranching and farming community and the local university (UM-Western). The plant effluent flows to the Beaver Head River, which is a blue-ribbon trout stream requiring the highest quality treatment. This upgrade project includes converting one of the plant’s existing lagoons to house the Biolac® System’s floating aeration chain and clarifier system. The project also includes a new head-works, sludge drying beds, equalization and ultraviolet facilities for disinfection. Compared to other systems, this cold weather Biolac® System provides considerable cost-savings to the community because it does not require the construction of a brand new facility but just requires a retrofit of the existing facility while maintaining the existing plant operations during construction.

“The Biolac® System has a much longer sludge age than other processes,” said Chuck Morgan, product manager for Parkson’s Biolac®. “That makes it an ideal solution for cold-weather applications like Montana, because the system maintains its capacity for BOD, ammonia, nitrogen and phosphorous removal - even in the dead of winter.”

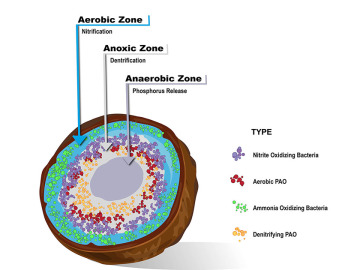

With its Wave Oxidation process, the Biolac® System creates oxic and anoxic zones that push the wastewater through multiple cycles of nitrification and denitrification inside the basin, without the need for pumps or additional basins. The configuration is ideal for BOD, ammonia and total nitrogen removal, while minor modifications also allow for phosphorous removal.

“Manion Engineering designed the system to handle ammonia, nitrogen and phosphorous requirements, because we know that tougher water standards will be coming in the future,” said Manion. “With only minor modifications, the Dillon plant can remove even lower limits of phosphorous and nitrogen.”

Municipalities in Montana and now North Dakota - along with other communities in parts of Northwestern U.S. - are acutely aware of the value of the natural resources surrounding them. As a result, with innovative designs like the one in Dillon, Manion Engineering and Parkson have shown that they are constantly working and leading the industry in maintaining these resources for generations to come.

For more information on the Biolac® System, please contact a local Parkson Sales Representative or Parkson Corporation at 1-800-553-5419 or http://www.Parkson.com; Manion Engineering can be contacted at 406-493-6325 or http://www.ManionEngineering.com.