Looking For Consistent Aeration Performance Over Time? Consider Jet Aeration

The VariOx™ jet aeration system is an aeration and mixing device used in numerous water and wastewater treatment applications. The jet aerator consists of an inner liquid nozzle and outer air nozzle. Liquid from the tank is recirculated through the inner nozzle at a high velocity. Concurrently, air is fed into the outer nozzle where it is combined with the high velocity liquid from the inner nozzle and discharged as a high energy plume. Air to the nozzles can be varied, or turned off, allowing the system to be used as both a mixing system and an aeration system. Some of the benefits of jet aeration include:

Benefits

Separation of aeration and mixing

High dirty water oxygen transfer efficiency

No loss of jet efficiency over time

Robust construction

Long equipment life (>25 years)

Ability to mix and aerate deep tanks

No electromechanical components inside the tank with dry pit pumps

Parkson’s VariOx™ jet aeration systems have been installed in many different applications – each with specific requirements that made the jets an ideal fit. Some of these include:

Applications

SBR systems

Oxidation ditches

Equalization tanks

Aerobic digesters

SBR (Sequencing Batch Reactor) Systems

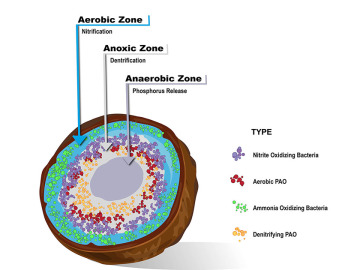

SBR systems are operated in a batch process where aeration is intermittent. While the intermittent aeration/constant flexing can reduce the efficiency and longevity of fine bubble diffusers and lead to premature wear, this is not the case with Parkson’s jet aerators. Jets are manufactured from FRP, which provides a high level of corrosion and abrasion resistance, and therefore, have no wear points. Additionally, the jet aeration system is designed to keep the tank contents in a complete mix mode with varying amounts (or even no air) during treatment steps where an anoxic environment is required. This feature allows for better process control compared to diffused air systems, where aeration provides mixing energy and can limit the ability to control dissolved oxygen (D.O.) levels.

Oxidation Ditches

Oxidation ditches have traditionally been mixed and aerated with surface mounted equipment such as brushes, rotors or slow speed aerators. Surface mounted equipment typically requires a shallow basin depth to maintain complete mix and reasonable oxygen transfer efficiency and can take up a large footprint. Jet aeration systems are just the opposite. Jets are mounted to the basin floor and rely on water depth and bubble residence time to achieve a high level of oxygen transfer efficiency. Ditch depths can range from 12’ to as high as 24’, maximizing oxygen transfer, greatly reducing footprint, and resulting in construction cost savings. Additionally, independent control of mixing and aeration allows for complete mix in the ditch, while varying blower speeds control dissolved oxygen levels.

Equalization Tanks

One of the main characteristics of equalization tanks is operation in a fill and draw mode, which creates varying water levels and makes mixing and aeration challenging. Jet aerators are mounted close to the tank floor (typically 1.5’ above the floor) to allow for effective mixing with only a few feet of water in the tank. Arrangement of jets varies based on size and geometry, but in all cases, they are configured so mixing energy reaches all areas of the tank (even at low water levels). An added benefit is that the FRP and stainless-steel components are not damaged or degraded when exposed to extreme temperatures and sunlight, so the EQ tank can remain emptied for extended periods of time. Parkson offers both jet aerators and jet mixers for EQ tanks. The jet mixing nozzles are designed to mix only and do not provide aeration.

Aerobic Digesters

Aerobic digesters can also operate at highly varying water levels, so jets provide many of the same benefits as with EQ tanks. The VariOx™ jets utilized in digesters can mix sludge with solids concentrations up to around 3% and will pass a 2” solid. The high solids concentration does not cause fouling of the jets (fouling can be a problem with fine bubble diffusers when used in this environment). Independent mixing of aeration saves on energy consumption, especially since most aerobic digesters have much less oxygen demand versus a typical aeration basin. Blowers can be used intermittently or operated at lower speeds to maintain a target D.O. level, optimizing power usage from blowers while utilizing the liquid mixing energy (from the jet pump) to maintain a complete mix condition in the tank.

Parkson welcomes the opportunity to provide project specific VariOx™ recommendations for any applications requiring aeration and / or mixing. Please contact Parkson for additional information on jet aeration systems and applications.