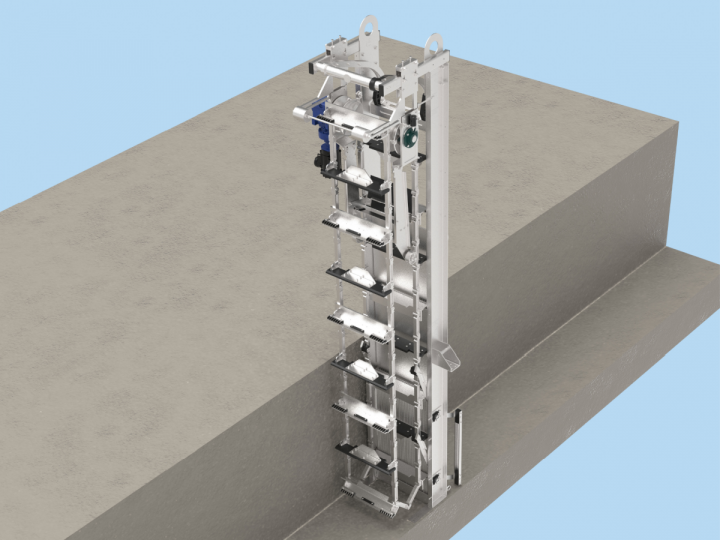

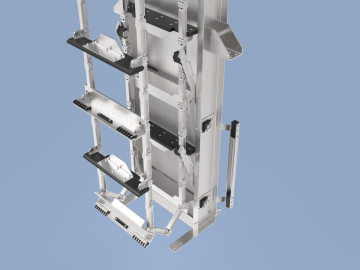

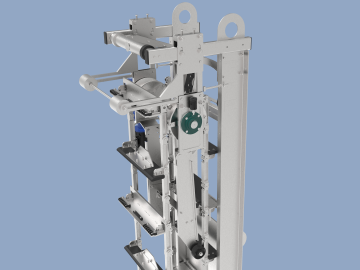

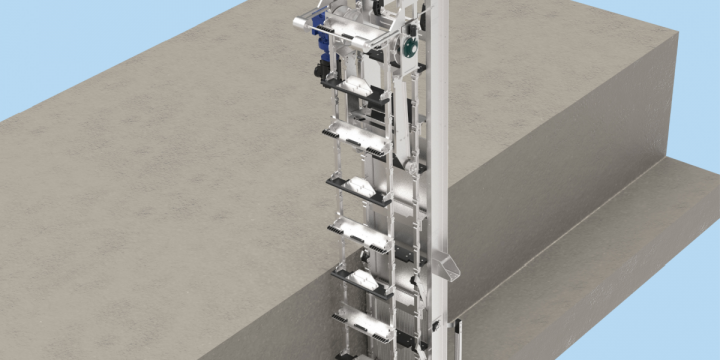

The new Aqua Caiman® Vertical screen takes our successful inclined articulating rake unit to the next level by allowing it to be used in locations requiring a very steep or vertical mounting. This mounting option is ideal for tight channel requirements in new or existing installations, and means minimal headroom is needed for indoor installations such as pump stations. Our design engineers developed two new, special features that both allow the Aqua Caiman flexible rake system to operate reliably and efficiently in the vertical mode, and also provide additional rake engagement force for removing solids from the bar rack.

The Aqua Caiman Vertical requires no lower bearings or sprockets, as the unique geometry of the flexible chain eliminates the potential for any jamming or fouling with solids in the channel. Service in hard to reach areas is eliminated. Parkson’s design engineers put their expertise into components where strength matters the most. Our chain link design is the heaviest in the industry, providing long lasting service and large lifting capacity of the toughest, heaviest debris. Our frame design is stronger than ever and highly efficient, helping reduce manufacturing costs, while allowing screen discharge heights up to 50 ft. The Parkson wiper arm design and new Expulsionator™ solids removal system make the Aqua Caiman Vertical screen an improvement over just about every aspect of the industry standard articulating rake screen.

The screen bars used in the Aqua Caiman Vertical screen are individually removable and replaceable without requiring any welding. Screen bars, available in tear drop or rectangular, include increased strength cross support design components and reduce headloss across the screen.

One Source for Screening Handling

The Aqua Caiman can be used in conjunction with Parkson's conveyors or wash compactors to complete the screening system. By providing single source responsibility, Parkson helps streamline communication and saves valuable time and resources while ensuring the highest quality standards. Additionally, product support is entirely sourced in the United States - from engineering to manufacturing, field service and spare parts warehousing.

Looking for additional information? We're here to help.