Principle of Operation

Solids contained in the wastewater flow are captured on the screen media and carried upward on the plate panels to discharge at the rear of the unit. Panels are available in stepped shape, or convex with lifting rakes, both capable of carrying large solids. At the discharge point, the plate panels are cleaned with a brush assembly and water spray. The enlarged drive sprocket enables the brush and spray to make the most efficient cleaning contact with the panels.

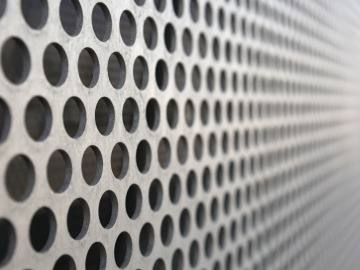

The screen media is available in a variety of openings, with 1/4" (6mm) the most common. In some instances, perforated screens have shown to remove higher quantities of solids than other types of in-channel screens.

Design Parameters for the Aqua Guard PF

Standard screen widths are 2.0’ to 9.0’ with flow rates up to 150 MGD with the single largest unit. Two frame styles are available depending on space and channel depth requirements. Type A is a pivoting design and Type T is a stationary design.

The perforated plate screen can be installed at angles of 60°, 75°, and 85° depending on the frame and model selection. For maximum operation efficiency, greater loading rates and higher solids removal, the recommended angle of inclination is 75°.

Movement of the screen can be continuous or intermittent; however, intermittent operation is recommended. This allows a mat of solids to build on the perforated plate media, which increases the solids capture rate.

Looking for additional information? We're here to help.