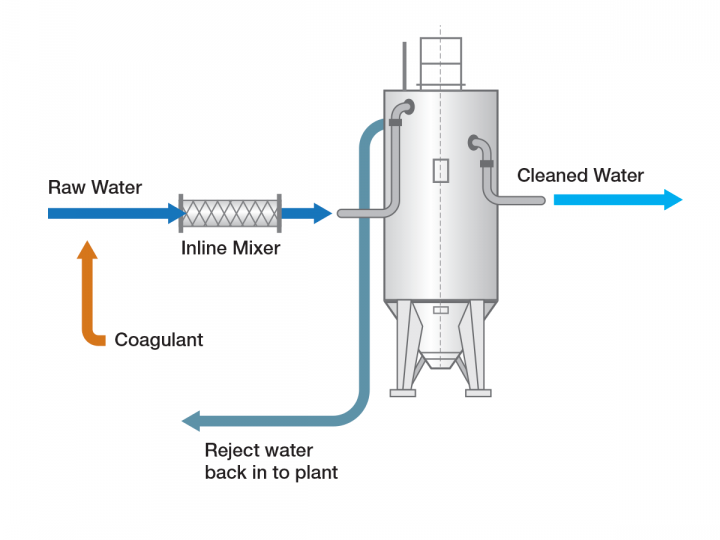

The DynaSand® Continuous Contact Filtration (CCF) process makes it possible to carry out coagulation and separation directly in the filter bed to produce a very high-quality filtrate. This even applies to waters needing large doses of coagulation chemicals and/or containing high levels of impurities.

The DynaSand continuous contact filtration process eliminates flocculation, settling and backwash water tanks. This reduces equipment volume by as much as 85 percent compared to conventional chemical treatment. Chemical usage can be reduced to 20-25%.

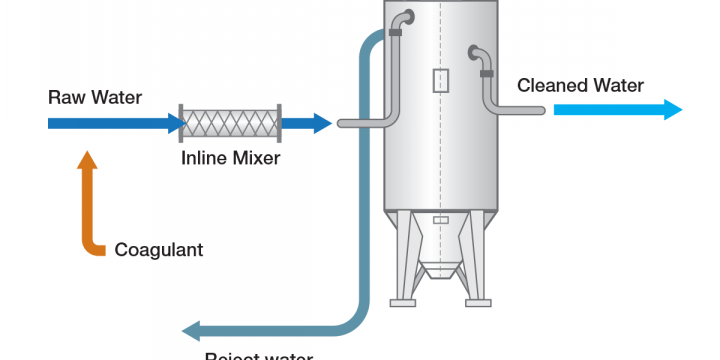

In the CCF process, chemical dosing equipment introduces coagulation chemicals into the feed line of the filter. A static mixer is provided to ensure good mixing of chemicals and raw water. Coagulation, flocculation and separation then takes place within the filter bed. The amount of precipitation chemicals such as PAC, aluminum, salts or ferric chloride is maintained either by feed-forward or feed-back control loops.

Looking for additional information? We're here to help.