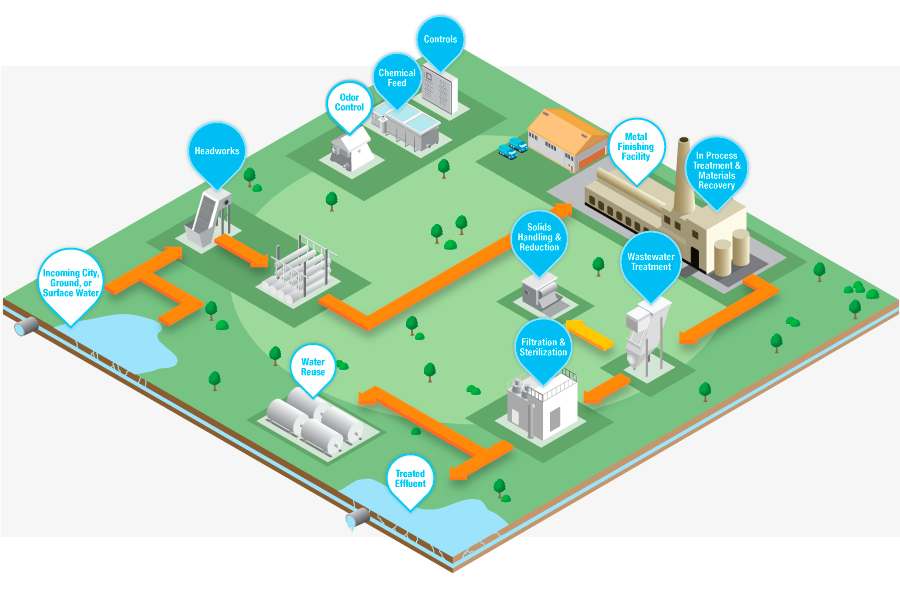

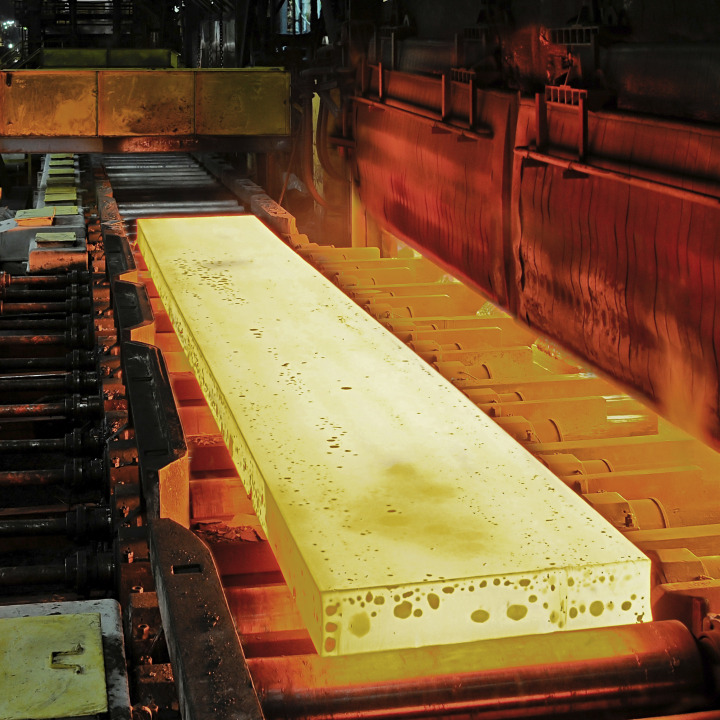

Water is a crucial component at every stage of metal processing and finishing. Large amounts of water are utilized throughout the entire process for cooling, washing, conditioning, lubricating, etching and plating. Up-to-date and efficient water management systems are crucial in ensuring quality, increasing plant output, and managing costs. With growing environmental restrictions and limited water availability, inadequate water treatment is no longer an option.

Metal processing and finishing water inevitably becomes contaminated with both reusable and waste materials that must be separated out. Parkson has the process expertise and specialized technologies for metal finishing water treatment. We efficiently extract these chemicals and materials from the wastewater in order to meet discharge and reuse requirements.

Beyond innovative treatment equipment, Parkson can provide entire turnkey systems for metal finishing companies including:

- Supervisory control

- Data acquisition

- Remote data monitoring

- Complete design, build, and operate (DBO) solutions

All of the systems mentioned above can be financed through Parkson to eliminate up front capital costs.

Click below to see our product offerings specific to each application.