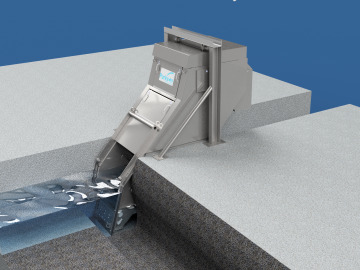

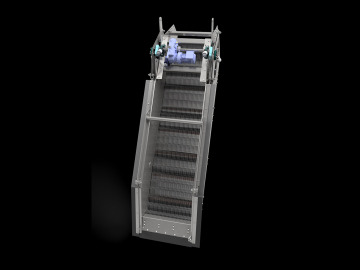

The Aqua Rhino™ represents the next generation step screen, providing unmatched durability, ease of operation and ultimate protection for your downstream process equipment.

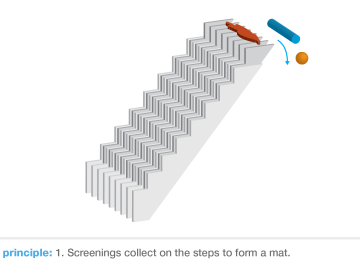

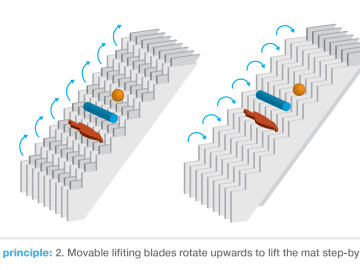

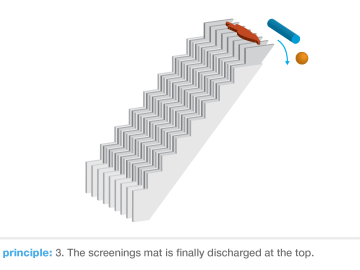

Operating Principle

Aqua Rhino Escalating Screen technology consists of rows of self-cleaning screening bars in a staircase configuration. Every other bar in this configuration is fixed, while alternate bars are part of a moveable fixture. This fixture of lift blades rotates, or revolves, upwards so as screenings are retained on the steps and form a mat, they are lifted step-by-step for eventual discharge at the top.

Design Parameters

Parkson Design Engineers worked closely with the marketing team to identify the weaknesses of competing technologies and make significant improvements in the Aqua Rhino step screen offering. At the top of customers’ wish lists was durability. This screen type in general offers low headloss, has no carry over or brush to maintain, and produces dry and uniform screenings. However, a myriad of issues end up driving end users to consider alternate technologies.

These issues include lifting blades bending, side frames twisting, abrasion due to grit at the bottom of the screen, and weaknesses in the typical sprocket and chain drive system. To address the blades bending and side frames distorting, Parkson engineers gave the Aqua Rhino the thickest lifting blade and side frame combination available on the market. Both components are up to 50% thicker than leading competitors.

To better manage grit buildup at the bottom of the screen, Parkson engineers utilized UHMW Polyethelene spacers, as well as, an optional grit washout system to minimize grit buildup in critical areas. Finally, the typical chain and sprocket drive system was eliminated in favor of a highly efficient and much more robust direct drive linkage system. The end result is that the Aqua Rhino is the most robust and durable step screen offering on the market today.

Aqua Rhino technology is an ideal screen for a wide range of municipal and industrial fine screening applications. It has proven extremely adept at handling flows containing high fibrous-like content. Screen openings range from 1/8" to 1/4" for clean water flows ranging from 0 to 75 MGD.

Looking for additional information? We're here to help.