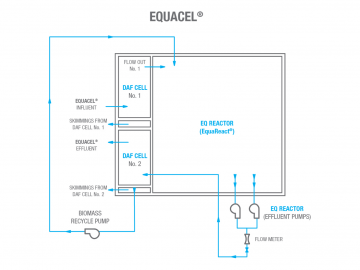

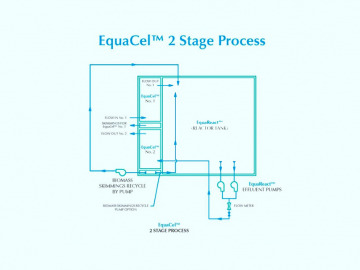

The EquaCel® process provides industrial owners and operators with a compact, efficient single-stage or two-stage high rate activated sludge treatment system. The system utilizes a primary DAF Cell for removal of FOGs and initial TSS. The DAF is followed by an Equalization Reactor, as part of the EquaReact® process, to combine hydraulic flow equalization and biological treatment in one reactor tank for removal of Soluble BOD, Ammonia-N and TKN. Treated wastewater, from the Equalization Reactor, is then pumped at a constant flow rate into a secondary DAF Cell, or clarifier, for biosolids clarification and recycle before discharging final effluent to the POTW. Tanks can be poured-in-place or pre-cast concrete, prefabricated steel or stainless in which one or more DAF Cells are combined with EquaReact in one common structure. Incorporating Parkson’s EquaJet® mixing, aeration and transfer system can bring added benefits by reducing the system footprint and offering an efficient biomass recycle method between tanks.

EquaCel is an Excellent Industrial Pretreatment System for Reducing:

- Soluble BOD

- Total BOD

- TKN

- Ammonia-N

- Phosphorus

Looking for additional information? We're here to help.