The EcoCycle SBR™ from Parkson combines industry leading DynaPhase Control™ technology with high efficiency treatment schemes designed to provide reliable and flexible performance for today’s stringent effluent needs. The EcoCycle SBR is a true sequencing batch reactor design, which allows for an ideal anaerobic/anoxic fill period, perfect for biological phosphorus removal and nitrogen removal. The true-batch design will also allow for a perfect quiescent settling step, promoting ideal sludge settling and compaction before the decant of the treated effluent. Our sequencing batch reactor basin designs are not limited by basin geometry or configuration. Deep tank sequencing batch reactor (SBR) basins are encouraged for better O2 transfer, which can lead to reduced operating expenses.

All required treatment steps will occur within a single reactor basin, without the need for any clarifiers or sludge recycle. The basic cycle structure would follow anaerobic/anoxic fill, react, settle, decant and waste sludge. All cycle set-points would be operator adjustable to allow the system to be configured for the specific needs, all in real-time.

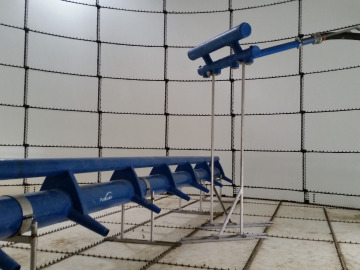

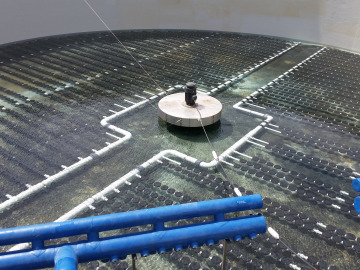

The Parkson EcoCycle SBR™ is built on the principle that keeping electro-mechanical components out of the wastewater is a desire of operation staffs, and allows for reduced maintenance. The Parkson SBR will also offer the widest range of aeration and mixing components on the market, from the VariOx™ jet aeration system to a complete offering of diffused air (fixed and retrievable) and mixers (floating or submersible). Parkson’s DynaCanter™ is a floating, solids excluding decanter designed to remove the treated effluent supernatant at the top of the basin, just below the water surface. The DynaCanter™ does not require any in-basin actuators or drive mechanisms to operate the unit, and thus reduces the potential for units to be taken out of service. Each unit will be sized to handle peak flows, should the need arise for a flow-through scenario.

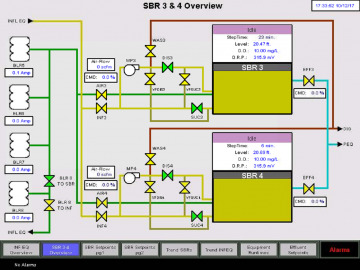

The brains of the EcoCycle SBR is the technologically advanced DynaPhase Control™, which will dynamically adjust the treatment steps of the sequencing batch reactor cycle based on incoming flows and loads. The control strategy will monitor flow and dissolved oxygen to allow for the automatic adjustment of the cycles to ensure proper treatment. During periods of low flow, the system will be adjusted into an “Energy Saver” mode by reducing the amount of aeration provided to the basins. During peak events, the controls will maintain the appropriate aeration percentage comparative to the flows and loads coming to the SBR. Operator changes to the controls set-points are acknowledged in real-time adjustments, which includes enabling or disabling a desired number of SBR basins. The Auto Detect feature will allow the system to make the necessary modifications automatically should a critical alarm or failure occur.

Sequencing Batch Reactor - Parkson's EcoCycle SBR Video

Looking for additional information? We're here to help.