Treatment Plant Operator- Here’s How a Florida Treatment Plant Team Deals With Hurricanes and Other Storm Events

Hurricane Irma was just the latest weather challenge fought off by the diverse and experienced operations team in Palm Coast, Florida.

Please excuse the staff at the Palm Coast Wastewater Treatment Plant No. 1 for complaining about lousy weather.

Hurricane Irma was just the latest in a series of storms and wet-weather events that have kept them busy managing high flows in the plant and collections system. “In my 36 years in the profession, it seems like this has been one of the most unusual as far as rainfall is concerned,” observes Danny Ashburn, manager of wastewater operations. “It started raining in July. On top of that, we got a hurricane and then two nor’easters that funneled rain on us for 36 hours.”

The 15 inches of rain on already saturated ground doubled the plant flow and made it challenging to keep the system operating. “It affected us pretty heavily,” Ashburn says. “The longer it goes on, the more susceptible we are to failures.”

But Ashburn, chief operator Pat Henderson, lead operator Marco Pubill and their team have been up to the task. The 6.8 mgd (design) plant has maintained compliance despite the weather. It received a 2016 Plant Operations Excellence Award from the Florida Department of Environmental Protection and Florida Rural Water Association.

Advanced treatment

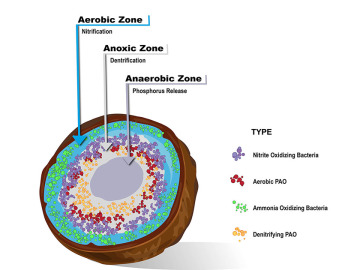

The plant serves 82,000 residents plus commercial accounts in Palm Coast, which stretches for several miles between St. Augustine and Daytona Beach. Built in 1972 and expanded four times since, the facility uses biological nutrient removal and advanced filtration to achieve a high-quality effluent that is mostly reused for irrigation and groundwater recharge.

From the influent wet well, raw wastewater passes through a pair of vertical mechanical bar screens (Parkson) and then to a grit removal system that consists of a cyclone section and a screw compactor section (Waste Tech). Three 15-foot-deep racetrack oxidation ditches follow, measuring 125 by 55 feet, with surface aerators and mixers.

Click here to read the full article.